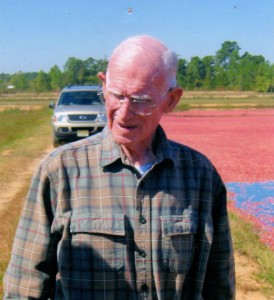

If it’s springtime, it must be time for a visit from Dr. Joan Davenport! Joan, a former researcher for Ocean Spray, works with Pine Island Cranberry to provide guidance on fertilizer, water, and nutrients, as well as general PIICM management. “At this point in the growing season, we are evaluating the plants for fruit potential and trying to develop recommendations for applications between bloom and fruit set. To do this, I look at hook, the length and color of the new upright growth, and the amount and color of old leaves, including looking for leaves from two growing seasons ago,” Joan says.

“This year Joan came a week later than usual because of the cool spring; the buds were still tight when they are usually beginning to break,” says PIICM Manager Cristina Tassone. “In order for Joan to make a good recommendation, we want to at least be a little past roughneck. The timing this year was perfect. We were able to complete our roughneck fertilizer plan before she came. The growth stage was between hook and scattered bloom. We were able to see the potential crop, and she was able to make some recommendations that she would not have seen if she came a week earlier. We were also able to walk the bogs comfortably with the mild weather; we are usually very hot and watching for wilt as we walk the bogs in May with Joan!”

New Production Manager Mike Haines was pleased to see Joan. “There aren’t really textbooks about cranberry cultivation,” he says. “So it’s great to get a chance to actually walk through with Joan and get a practical education. I can learn both what kind of nutrition the plants need and also why they need it. This is the first time I’m learning a lot of this stuff, so I’m glad to have her here to answer questions. It makes me confident that before too long I’ll be able to make these decisions on my own.”

In general, Cristina says, “This spring has been different for us. We’ve had quite a few frost nights and not so many sunny and hot days to move the plants. It seems like the plants grew over two weekends. Now we are back to cooler weather and the flowers are just waiting to pop. I estimate that all of our bogs are going to look different after this weekend where we are expecting sunny days and warmer weather.”