Safety is one of our ever-present goals at Pine Island Cranberry, and our team has regular meetings to keep everyone updated and to issue any necessary equipment.

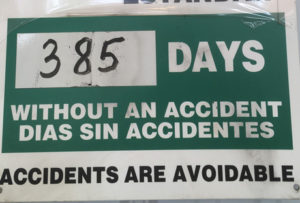

We also like to celebrate when our team hits important targets, and this month Pine Island has once again made it over a year accident-free!

“Safety is very important to us at Pine Island; it is an obligation we all share,” says COO Bryan vonHahmann. “Our team operates large, powerful equipment – sometimes in inclement weather and tough situations, so they have to be safety conscious at all times, for themselves and fellow workers. We want our employees to go home at the end of the day in the same condition they came: that is, healthy and free from injury. Their families count on this! We continually discuss the value of safety to instill the behaviors that promote working safely.”

Prevention, of course, is a top concern. “The best way to keep everyone accident-free is to be proactive in setting up an environment that’s conducive to safety in the first place,” says Mike Haines. “Maintaining the dams, the equipment, the buildings; that means we’ll keep to a minimum any unexpected events that can lead to an injury. Making sure everyone is provided hardhats, ear protection, and gloves ensures that they’ll have them when they need them, and so does wearing them at any time an accident could happen. A lot of things happen before that ultimately lead to accident or injury or whatever, so staying on top of those little things helps make sure a bigger thing doesn’t occur.”

Safety training doesn’t just happen in the field, either! “The instructional videos on safety that Debra [Signorelli, our office admin] provides for our workers has insured the safety of our team,” says Matt Giberson. “The videos have helped seasonal workers understand the importance of chemical application. Debra is currently looking at additional training videos that will continually improve the safety around the farm. Another practice that we have put forth in recent years is the importance of head protection via hard hats. With the renovation process at full steam ahead, our team is around a lot of heavy machinery. So the use of hard hats and proper training of our operators has helped provide a safer working environment for all.”

Matt Stiles attributes a good record to good everyday practices. “Even if it’s a routine job, we always take the time to make sure we’re doing it right,” he says. “We’re careful with everything we do. And it’s not just the managers; guys like Juan Carlos and Jonathan and Israel make sure everyone is properly equipped and really keep a close eye out to make sure we’re all doing what we need to do.”

“I’m very proud that we kept all of our folks safe for a full year,” says Louis Cantafio. “In an operation as large as ours, with ‘whatever it takes!’ as our starting point, it can be very difficult for each of us to keep ourselves safe: ‘if I just reach a little further; if I just yank a little harder; if I just go little faster; if I just try a little harder; if I just do whatever it takes!’ We have all done it. We will all do it again. Real success, team safety, comes when we work to keep each other safe. ‘Let me help you with that; let me come with you when you pull boards at night or break ice; don’t forget forgot your safety glasses; back away while I raise this load.’ We have all managed to do it together for a full year. We will all come in tomorrow and work at doing it again. Great job on everyone’s part! Way to keep each other safe!”

CEO Bill Haines is especially pleased, and as a reward, we all got to go home a little early last week! “The team is working long hard days to get stuff done, just like all of us. And it’s a credit to them that they’ve done it safely and everyone goes home at the end of the day healthy,” he says.

Congratulations on another job well done, guys!