In January, we talked with Kylie Naylor about the hows and whys of installing swan string in selected bogs. Tundra swans migrate to the area every year from Alaska and northwestern Canada and are particularly fond of red root, a weed that competes with cranberry vines for nutrients. When they fly in to feed, they not only tear out the red root, they also tear out vines and leave enormous holes that damage the beds themselves. The strings help keep the swans out of the bog by limiting the space available.

Now that spring is here and the swans have moved on until next winter, new full-timer Casey Koehler (pictured, below right) and BCC intern Lisa Wassell (pictured, below left) are two of the team members assigned to remove the strings.

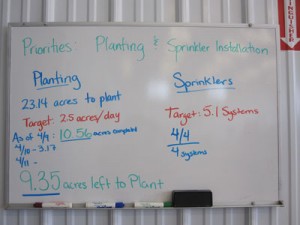

Casey, who came to us on a recommendation from team member Vincent Arnwine, has been with us since March and is having the time of her life. No stranger to outdoor work, she grew up taking care of horses on her family’s farm, as well as working on other horse farms and doing some office and field work with an archeological firm. In addition to removing the swan string, she has also worked with the sanding and planting crews as well as helping install sprinklers.

Her favorite task so far has been taking down the swan strings. “It’s been beautiful this week,” she says. “Working outside is the absolute best. It’s so much better than sitting in an office!” When asked what the toughest thing has been so far, she said she had a hard time with the sprinklers. “The new bogs were easy, but it was a lot tougher in the established bogs. But I worked with Caesar [Colon] on that, and he was a big help. In fact, everyone’s been really nice.” She’s looking forward to learning everything she can. “I’m learning how to drive stick! I’m going to train on the dump trucks, I want to learn how to run the excavator, and I can’t wait until harvest. That’s going to be a lot of fun.” She’s curious about the fairy-ring treatment, and has been learning about that process as well. “Casey has a lot of energy,” says GM Fred Torres. “And she’s always asking questions. It’s great to have someone on board who’s genuinely enthusiastic to learn.”

Intern Lisa Wassell came to us just as we were finishing up sanding, and is also no stranger to the great outdoors. “I was a veterinary technician for years,” she says. “Working with horses means spending the time outside. It doesn’t bother me at all.” She’s worked alongside Casey on most of the same tasks. “Whatever needs to be done,” she says. A nursing major, she’d worked with Standardbreds on a breeding farm for years, and decided to go back to school. She was job hunting and needed elective credits, and her advisor thought this might be interesting. “And he was right,” she says. “There’s something different every day. I’m not afraid of hard work.” She’ll be here through the summer and is looking forward to see how the growing season progresses. Some of her other priorities as an intern will be helping us with process improvement as well as documenting the processes for Integrated Crop Management.

Casey and Lisa work well as a team. Taking down the string is simple. “The real key is doing it as efficiently as possible,” Casey says. They cut the string and remove the rebar in a pattern that tries to make sure that they only have to pick up bundles for two bogs along an adjoining dam, then store or recycle as needed.

Pine Island Cranberry is glad to have women like Casey and Lisa on-board; it is always a pleasure to find people who are enthusiastic about what we do and have the drive to learn and develop new skills. It’s people like that who help Pine Island do everything we do better every day.