One of our projects that was bumped up after the effects of the Labor Day storm is raising the level of the dam out at Ox Pasture reservoir. Ox Pasture is the biggest reservoir on the main farm. Situated at the northernmost end and bordering the property now owned by the New Jersey Conservation Foundation, it is the primary source of water for the main farm.

During the Labor Day storm, the NJCF Franklin Parker Preserve lost some dams, making it necessary for us to break part of our Ox Pasture dam to relieve the pressure of the water coming down and to save some of our own bogs from from flooding. “If we can force it to break at one particular spot, it allows us to save more dams from breaking as well as protecting the fruit,” Tug Haines says. It will also help us if (when) we get more heavy rain in the future. The repair to Ox Pasture was made immediately along with the rest of the dams that broke around the farm in other high-water areas, as it was imperative to get back on track for the harvest.

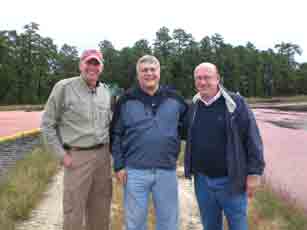

Caring for the place where we live, work, and grow not only means caring for our land and our environment, but for our neighbors as well. Raising the dam serves two purposes: reinforcing our own infrastructure by protecting our water supply, and helping our neighbors. While it benefits us in the future, it will also allow us to help the Parker preserve make the necessary repairs to their property.

Before we started raising the dam at Ox Pasture, we rehabbed existing turnarounds (places for trucks and equipment to pull over) and made three new ones so that it’ll be easier to get more trucks closer to the north end of the property. Dams are only made for one-way traffic: if we can find a way to allow for more traffic, we can get more more trucks out here at one time and do everything more efficiently.

The process itself is pretty straightforward. The truck goes to a clearing and gets loaded with sand:

The load of sand is then taken back to the dam and unloaded in front of a bulldozer:

As with our bog renovation projects, the leveling by the bulldozer is done with the help of a laser.

With so many trucks in circulation, we’ve been able to complete the project in less than a week, which will help us get started on the work repairing the Parker property.

While this project is our top priority at the moment, building up our dams is a yearly maintenance task, and our team will be checking up on other areas affected by the storm in days to come.