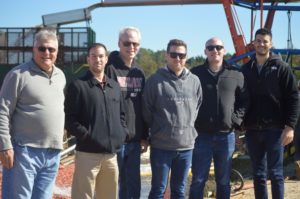

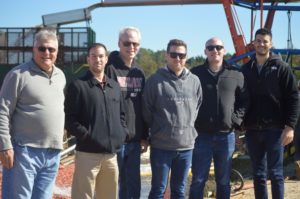

Mid-October means it’s time for one of our favorite annual traditions here at Pine Island Cranberry: a visit from George Giorno of Ocean Spray on his “Bog to Bottle” tour! George comes to see us every year, along with various account executives from some of Ocean Spray’s wholesale customers. This year, we were happy to see that George brought Greg McCann of Advantage Solutions for his fourth visit, as well as new visitors Jeremy Mitchell (also from Advantage), Danny Seijido from the Ocean Spray sales team, and Tucker Lynn and Victor DeJesso from Wakefern.

The group gathered at our main office, where they heard a brief farm history from CEO Bill Haines, and fifth generation grower Mike Haines and his sister Stefanie took everyone out to see how we do things in the pines!

We arrived at Red Road just as our team was beginning the process of gathering a freshly picked bed, and everyone got to go up onto the bog side cleaner’s platform to get a view from the top!

Then it was off for a close up look at the Gates Harrow in action before heading down the road to the Ocean Spray receiving station in Chatsworth.

These days, all the Haines family really has to provide is a driver; George’s knowledge and enthusiasm is tremendous, and he knows every single step of our harvest. “While the calendar may say fall arrives on September 21st, it really doesn’t actually arrive until our annual trip to visit the Haines Family at PICC in mid-October,” says George. “Yet another great day with Stef and Michael Haines this year, while also getting to visit with Bill upon our arrival, as we toured the farm with our guests from Wakefern Food Corporation and our agency partners from Advantage Solutions. For four of our guests, this was their first time experiencing the beauty of the Cranberry Harvest and for me, it was another day where I get to reignite the passion for my vocation and visit with a great Ocean Spray Cooperative Family who treat me as one of her own! Never a visit without learning something new from something old as PICC is continuously improving their harvesting operations in a meaningful, efficient and positive way.”

Greg McCann always has a good time, too, and never fails to ask interesting questions! “This being my fourth year of touring your bog, I learned something new, yet again,” Greg says. “With the hot weather being late this year, it really affects the color of the cranberries, as evidenced by the mix of white, pink and red colors in the Bog! Last year, they were more crimson red, at this point in October.”

We say this every year after George and his group come to see us: it’s always a pleasure to speak with people who are genuinely enthusiastic about what they do and are so willing to completely immerse themselves in a new experience. It‘s always fun to have George and his team here and show our customers how we really do things. It’s good for them, and it’s good for us. Thanks again, George, for everything you and your team do!