The daily routine at our cranberry platform is a simple but continuous process, and relies on constant communication between the team leaders and the packing house team, as well as between the packing house and the receiving station. It remains the same as always: each team on the bogs has been assigned a color: Orange, Blue, or Green. In order to properly track each team’s production, their bogs are assigned a different section on the packing house platform. Each bog is run through the blowers separately. The first load from each new bog has a post-it note attached to it with our Exhibit A number, or bog identification number. It is the team leader’s responsibility every day to let Mike Guest, our facilities supervisor, know what their plan for the day is and to keep him informed of any problems that might occur during the day.

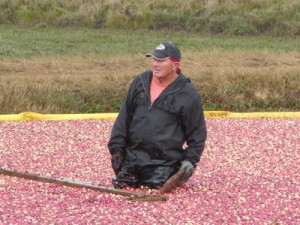

First, the forklift crew, led by Emmanuel Colon, unload the full cranberry boxes from the trucks coming out of the field. If the boxes are coming from the bog that Mike is sending through the blowers, then the forklift crew will dump the cranberries from those boxes into the hoppers. If Mike is not running that particular bog the forklift crew will stack the boxes in the appropriate spot for that crew on the platform. Once the cranberries are poured into the hoppers, they pass along the belt through the blowers, which are used to partially dry the fruit and remove as many of the leaves as possible. Once the leaves are blown out, the fruit drops onto another belt and from there move up the truck elevator into the waiting trailer. Team member Harry Mick keeps the loading moving; he signals our drivers, Josue and Pedro, to keep the trailer inching forward as each section is filled with fruit. It is then his task to halt the line when the trailer is full or the bog is finished in order to bring the next waiting trailer forward.

While all of this is going on, other team members are busy rinsing off the belts in order to keep the equipment as debris-free as possible. They also take advantage of pauses in loading to sweep up the extras and push them toward the debris pile. In addition, everyone pitches in when necessary to clear out the hoppers, which occasionally can get jammed. The last box out of a bog usually has a lot of leaves, grass, and other bog debris, and can clog the line and cause hold-ups both here and at the receiving station if we do not take care of it immediately. Therefore, the constant washing of the equipment and attention to detail by the packing house crew help keep our harvest running.

Mike always welcomes any ideas from his crew to improve the process. “They’re the ones who are on it every day; if they come to me and ask if we can try something, I’ll always see if it’s doable.” He especially relies on the assistance of Emmanuel Colon. Emmanuel, a seasonal team member for seven years, moved up to full-time to assist Mike Guest with our Facilities team. While every day during harvest time is busy, some days are especially hectic, and that’s when Mike relies on Emmanuel the most.

“He’s a hard worker,” Mike says. “Not only is he willing to do anything, he’s also willing to stop and ask questions if it’s something he’s not sure about; he won’t just bluff his way through it. I never have to worry if I have to go somewhere; when Emmanuel is left in charge, things get done and they get done right.”

A devoted husband and father of three, Emmanuel is also highly versatile with excellent technical skills. In his time here, he has helped build the new well at Caley, assisted with the new irrigation lines at Boricua, and done numerous carpentry jobs, both large and small.

“Emmanuel’s very flexible, with a great work ethic,” GM Fred Torres says. “I know he’s busy this time of year, but if I ask him to do something, he’ll get it done. And I don’t have to go back and check; if it’s on his list, it’ll get done. He’s organized. He writes it down, he keeps track.” We’re proud to have a team member like Emmanuel, who is always willing to do “whatever it takes” to help Pine Island Cranberry keep growing!