Pine Island Cranberry’s forest stewardship plan helps us to protect and improve resources by allowing forest practices to be implemented on the ground while maintaining a thriving forest ecosystem through prescribed burning, road maintenance, and boundary surveying, among other things. The cedar swamps of the New Jersey Pine Barrens help to filter and purify water by absorbing and filtering pollutants and sediment. Since the three most important things to the cranberry industry are water, water, and water, maintaining and protecting the cedar swamps are high priority.

In addition to certified New Jersey forester Bob Williams, Pine Island Cranberry has been working with Colin and Deborah McLaughlin of Advanced Forestry Solutions to make sure our stewardship plan is implemented in the most effective way possible. The McLaughlins have been in the business for about eight years. “We wanted to spend more time with family and enjoyed working outside,” says Colin. “We started out mowing, then realized it wasn’t a full-time occupation.” They started out working with pine and oak, then moved onto the Atlantic white cedar when they started working with us. “It’s a beautiful product,” he says. “It’s water and insect resistant, and it makes for great outdoor stuff.” In addition, “It’s good for the health of the forest to make way for new cedars.” When cedars come down, their seeds can help regenerate the forest when the conditions are right, if other hardwood species don’t invade, and if deer don’t eat the seedlings.

To that end, work has begun on our latest stewardship project out at Sim Place, by the Savannah bogs. Colin and Deb will be thinning the trees in an attempt to reduce the number of red maple seedlings, which have been a problem on those bogs in particular. Red maple is lovely in a forest, but invades cranberry beds as windblown seed. Removal of red maple is a big part of every grower’s weed control program, and hand removal has been effective but time-consuming. Managing the cedar stands should hopefully reduce the issue at the source.

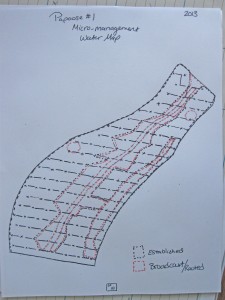

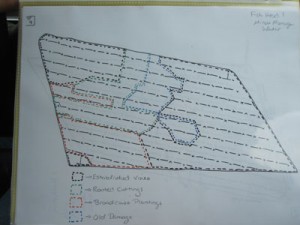

First, though, our team needs to make it easier for Colin and Deb to take their equipment into the forest, so they are building some access roads.

This means making sure the water flow is unobstructed. To make this happen (and to reduce waste), we use pipe leftover from building our floodgates.

CEO Bill Haines was pleased with how the work is turning out. The real test occurred when the team took the water off for ice sanding, and everything held up perfectly!