Everything you need to know about the founder of Pine Island Cranberry is noted in the minutes from the January 1893 meeting of the American Cranberry Growers Association:

The first topic for discussion, “Failures in Cranberry Growing and their Cause”, was opened by Capt. Haines, Mr. Budd being absent.

He said he had never failed in cranberry growing and hence was not a good judge.

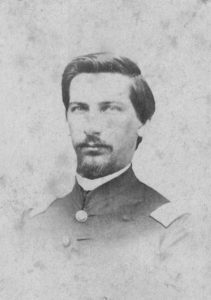

Martin Luther Haines was born in 1837 in Vincentown to John and Lydia Woolston Haines, and lived in Vincentown for most of his life. Before he was a cranberry grower, he was a teacher, a soldier, a lawyer, and an entrepreneur. After serving as Captain in the Union Army during the Civil War with Company C of the New Jersey Volunteers infantry, he became interested in growing cranberries and owned several bogs in Southampton and Tabernacle Townships including the Birches, Two Bridges, and Burr’s Mill. But the Pine Island story begins in 1890, when he and his friend George McCambridge bought some bogs as well as some uncultivated land at Pineworth and Hog Wallow.

“It was tough back then,” CEO Bill Haines says. “Cultivating a cranberry bed at the time was all mostly handwork. The first area he and George planted was Worth Tract. When they split the partnership, Martin started taking cranberries out of the wild on the Hog Wallow side of the road. We think Mammoth bog was the first one he planted on that side.” Since cranberries are perennials, there is even a small patch of vines we believe may have been planted by him that are still producing.

One favorite family story: when he first started cultivating his own land, his wife, Ella, attempted to change the colorful name and call the place “Tranquility” after a large swamp on the property. But if you know Pineys (and Cap Haines), you know that wasn’t going to stick, and of course, the name remains “Hog Wallow” to this very day.

“He lived in Vincentown, mostly, but built a house to stay here,” Bill says. “He died 48 years before I was born, so I don’t have any real stories. My grandmother, though, grew up in Vincentown and remembered him from when she was a little girl on Mill Street. Her main memory was of him always sitting on his porch with his nose in a book while propping his ‘big feet’ on the porch railing.”

After Martin’s death in 1905, the property passed to his sons Ethelbert, Ernest, and Ralph. Ethelbert and Ernest took over the everyday operation of the cranberry bogs, continuing to expand the property, along with the others at the Birches, Burrs Mills, and Goose Pond. Eventually Ralph, the youngest son (and Bill’s grandfather) became more involved as well…but that’s a story for a future blog post!

The best summary of Martin’s life, though, may be this amazing tribute from the Burlington County Bar Association after his passing.

Martin L. Haines, whose decease we mourn, was born at Vincentown, in our county and state, on the 19th day of March, A.D. 1837, and after a long and honorable career as a student, soldier, teacher, lawyer, and agriculturalist, died rather suddenly at the age of sixty-eight, and was thus removed from life’s active scenes. His death shadows his relatives, friends, and companions with a pall of grief.

Mr. Haines began life as an industrious student. At the age of twenty-three his studies were interrupted by his enlistment, on the 13th day of March, 1863, as a Union soldier in the war of the rebellion. His active army services extended over a term of three years. He rose to the rank of captain in Co. C, of the 34th New Jersey Volunteers, and after a valiant career was honorably discharged on the 18th of April, 1866. Returning to his home, he became a teacher and taught in the Burlington County public schools until 1870, when he entered his name with Justice Charles E. Hendrickson, at Mount Holly, New Jersey, as a student at law, and was admitted to the bar at the November term, 1874, being admitted as a counselor at law three years later. For twenty years he practiced law successfully, having an office at Mount Holly and residing at Vincentown. While Captain Haines never discontinued his office up to the time of his death, yet since 1893, he occupied a major portion of his time in cranberry culture, in which he was remarkably successful in securing bountiful yields and a considerable fortune.

Captain Haines was an extensive reader and more of a student than was generally known. He loved knowledge and held his profession, and its learning, as life’s greatest adornment. He hated sham, detested hypocrisy, and had a low estimate of those in his profession who stooped to technical and mean advantages. No characteristic stood out more prominently than his independence, and cast, class, rank or fortune showed no sycophant in Captain Martin L. Haines. Captain Haines’ life was clean and honorable, both private and public, and we are honored by his connection with us as a fellow member of the bar, and sincerely mourn the loss of our friend, companion, and brother.

Captain Haines married Ella Joyce, of Vincentown, and she, three sons and a daughter survive him, who have our sympathy and tender condolence in their great grief.

We move that this testimonial be made a part of the record of this honorable court and that a copy be forwarded to his family. Respectfully submitted, JACOB C. HENDRICKSON, SAMUEL A. ATKINSON, CHARLES EWAN MERRITT, SAMUEL W. SHINN, WALTER A. BARROWS.

Pine Island Cranberry is proud to be continuing our founder’s hard work!