There have been a couple of changes to the Pine Island office team since we last checked in. The biggest change, of course, was when CFO Holly Haines stepped down in December to head the Haines Family Foundation full-time, and former controller Joann Martin stepped up to fill the position.

“Holly is a tough act to follow,” says Joann. “People ask about her all the time. She was born into this, she grew up with it, it’s in her blood.” However, Joann has become fundamental to Pine Island Cranberry in her own right. As CFO, Joann is responsible for the budgeting and all the monthly reports, as well as taxes, bookkeeping, and all the insurance for the farm: liability, workers comp, heath insurance, and general liability (for buildings and residences). She also works closely with the other managers on their budgets so that everyone is on the same page. “I love how everyone is coming together,” she says. “I like numbers, but I like being part of the whole operation and not just being a numbers person. I love getting out onto the farm to see what’s going on; it helps me understand it better. Plus, it means I’m not doing the same thing every day. Every day I’m learning something new about the company, about the team, about the industry.” Out of all of it, though, she loves harvest the best.

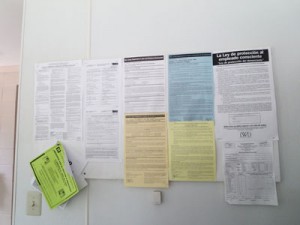

We also have a new addition to the office team, Staff Accountant/HR Coordinator Stacey DeLaurentis. Stacey started with us in June and has immediately taken to the place. Stacey grew up in Sweetwater and has lived in the area her entire life. Among her many tasks are payroll, employee benefits, the profit sharing plan, and payables. When the part-time team members come in, Stacey makes sure they’ve filled out all the required documents. She also works with GM Fred Torres on time sheets, as well as tracking any missed time by any team member. In addition, she will soon start working with PIICM manager Cristina Tassone on OSHA compliance. “One of the things I just did was head to the big camp putting up new posters to make sure we’re in compliance with federal and state requirements.” This is going to be Stacey’s first harvest at Pine Island, and she’s very excited about it. “Cristina has been taking me around to see the operation. I read it on the blog, but it’s different being able to stop and see for myself what dewberry is, or how they crown dams,” Stacey says. It serves a couple of other purposes as well. “When I do their time sheets, I can now picture what they’re doing. Plus, if they see me out there and know who I am, it’s hopefully a little more comfortable for them to come in and see me for something if they need to. They have a face for the name.” She is also very pleased at some of the projects she’s been working on. “I was able to come in and make the time sheet system my own,” she says. “It’s a different system than I’ve used in the past, which is to be expected. But I was given the latitude to make any changes I thought could work. It’s great.”

The rest of the office team remains the same. Intrepid administrative assistant Debra Signorelli is well into her second year with us and has become an indispensable member of the team. She does everything, and by that, we mean everything. “The most important thing I do is assisting Bill,” Debra says. “He’s very busy and involved in so many different things, so I try to keep life as simple as I can for him. He has a lot of big things to worry about so I take care of the little things. That’s what I do for everyone here, really. Everyone is busy with their departments, everything is on a schedule, especially with farming. So I’m just here to help everyone so they can worry about the big picture: running errands, making copies, supplies, minutes, prepping for board meetings. Whatever it takes to run an office. It’s a growing office and a growing company; if you have positive efficient people it becomes contagious. It makes you want to do something better. Every day I learn something new. It keeps you green, keeps your energy level up!” And with that, she’s off to start a new project Bill found for her in the middle of her interview.

Finally, we have Stefanie Haines, your webmaster and blogger, who finds it awkward to talk about herself in the third person. It’s been about a year and half since the blog started, and since then we’ve covered a year in the life of a cranberry operation and have moved on to some more in-depth exploration of what we do here and what it means to us, the community, and even the environment. We have expanded into social media and now have a presence on Facebook, LinkedIn, and Twitter, and are exploring ways to make Tumblr work for us. It’s a job that combines the best of both worlds: being in a fun, supportive office environment but also being able to get out into the woods and the water. The best part of it all, though, is being able to talk to our team. I might write the blog, but those are just the words: it’s really our team who tells our story.

CEO Bill Haines agrees: “One of our core values is continuous growth, and you can’t grow faster than the team you have in place. Our entire staff here at the office is not only efficient, but are always looking to make Pine Island better, and doing it in a way that actually makes it fun to come to work.”