We’ve posted before about the new scraper we commissioned over the winter. Over the past couple of weeks, our team finally got a chance to put it to work.

While our team had tested it after arrival, last week they put the new land leveling blade attachment to work on the renovations at 11 Acre and Benny’s. “The land leveler we already have is great, but it’s getting worn out,” explains Facilities/Equipment manager Louis Cantafio. “We like the model we have, but it’s been discontinued. So when we commissioned the new machine, we decided to make it multifunctional and did some re-purposing. We made the new blade straight and a fixed width, as opposed to the crowning blade, which is curved and able to be expanded if necessary. We also made it wider than the old leveler.”

“As part of the project we put a laser receiver and electronically driven valve on the tractor to make leveling easier,” Louis says. “The tractor had one before, but it was just the indicator. Now the operator can just pay attention to driving while the laser and the controller communicate and make necessary corrections. Plus, the wider blade helped us get the edges of the bog, which previously had to be done after the main leveling was finished. Speed and communication have helped us get the leveling done forty percent faster, which is huge.”

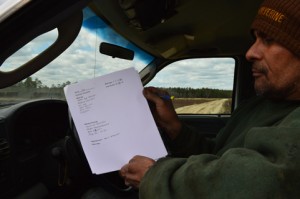

So far the team has had to change the blades twice: once to put on the new leveling blade and once to put the crowning blade back on. In both instances it took the team about 45 minutes to make the conversion. “It was a little bit of work, but we’ll get better at it,” Louis says. “The time we spent is a worthwhile investment. And as it turns out, it works very well. We had to do some custom modifications to make it work and they turned out fine.”

Team member Junior Colon, who is scraping dams this week, agrees. “The wider blade on the crowner makes things a lot easier,” he says. “There were some new controls to learn, but once you pick it up everything’s great. The whole thing tilts, which makes it easier to smooth things out, and having the ability to expand or retract the blade is a huge help. Once you know which dam you’re on and what it needs, it works out perfectly.”