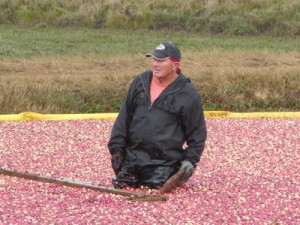

Last month, we talked with Assistant Manager Mike Haines about drainage repair and the opportunities it gave us for collaboration with our fellow growers. “The cranberry community isn’t so huge that businesses will make equipment especially marketed to us,” Mike said at the time. “A lot of what we do is done by working together to improve what we have.”

While we’d been borrowing the current set-up from fellow grower (and fantastic neighbor) Bill Cutts, our equipment team started working on building one of our own, making improvements based on team recommendations. This week, equipment team member Fred Henschel is nearly finished!

“This machine does everything,” Fred says. “It holds the rolls of 2-inch underdrain, it works with either a skid steer or a tractor with a three-point hitch…it’s been designed to fit just about everything we have on the property. Whatever is available.” He also designed it with some flexibility in mind. “It was designed based on input from the guys who will be using it, but if for some reason they really don’t like it, the entire center implement can be unbolted and I can place it on a different frame. It’s a prototype; nothing like this had been built before, as far as I know, so I can remake it until everyone’s happy with it.”

The entire machine was designed to be as efficient as possible. Fred looked at how the machine was cutting vines and decided he wanted as sharp an angle as he could get so it wouldn’t push the vines out as far; at that point, the roller would be able to pack the dirt right back down again. Having the spools right on the machine should also increase the speed. “What they can do is tow the trailer with all the rolls, put two on the machine, and keep going. Probably be able to go at three or four times the speed.” He’s also made some modifications for tools. “The basket here is for their tape and their knives, in case they need to add more pipe. This way they can take care of it right there and keep going.” As for changing out the rolls, he attached spinner handles for everything so nothing needs a tool to unfasten.

While the water is on the bogs for the winter, our equipment team is looking forward to seeing how the new machine works in the spring; we’ll be checking back then!