Last week several Pine Island Cranberry team members attended the annual American Cranberry Growers Association (ACGA) summer field day at the Rutgers extension center. While several topics are similar to those discussed at the winter meeting, the field day is a chance to go out and explore the researchers’ valuable work first hand.

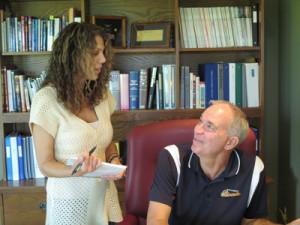

The team members in attendance all greatly enjoyed the hands-on discussions and opportunity to speak with other growers, especially the growers visiting from outside the region. “This was the best-attended meeting we’ve had in New Jersey,” says PIICM manager Cristina Tassone. “It was great to see and have an opportunity to speak with growers and researchers from other cranberry-growing regions.”

A lot of the excitement came from the research on new varieties. “It was pretty exciting seeing a lot of the new varieties,” says supervisor Jeremy Fenstermaker, a thought echoed by Cristina, who enjoyed listening to Jennifer Johnson-Cicalese’s talk on the results of her fruit rot resistance trials. Team member Matt Giberson adds: “Getting something crossed with the more resistant varieties could be huge news for us in regard to fungus and rot resistance.”

Our team also got a lot from the indoor talks on both precision irrigation and phenology models for certain pests. “I thought Jean Caron’s talk was on target with what we’ve been focusing on for the past few years, especially in new production,” says Cristina. Jeremy thought so as well: “It was nice to have some focus on water management for other reasons than rot; it’s such a big part of our operation.” Assistant Manager Mike Haines also appreciated the perspective from growers and researchers from outside New Jersey, especially Wisconsin researcher Shawn Steffan: “Shawn was able to take something complicated [the concept of degree days and their use in pest management] and give us a clear explanation of how it works and how we can apply it.”

The show and tell segment was a big hit again, just as it was last year. Mike: “Shawn Cutts’ presentation on dodder was interesting. Dodder’s such a persistent problem; it comes back every year no matter what you do. It’s really good to hear from other people about possibilities for a new approach.” COO Bryan vonHahmann, attending for the first time, was very impressed with the show-and-tell section as well. “Sometimes the simplest things are the best things. The thermal weed control technique seems to be faster. We’re also trying the 2-inch underdrain that Bill Cutts is using; it’s much easier on the plant beds.”

Just as he does every year, Cesar Rodriguez-Saona put together yet another fantastic program. Overall, our team came away impressed with the varied presentations and pleased to have new ways to improve our operation!