This week, it was once again time to hear from one of our favorite visiting scientists, Dr. Joan Davenport! Joan, a former researcher for Ocean Spray, works with Pine Island Cranberry to provide guidance on fertilizer, water, and nutrients, as well as general PIICM management.

“This was an especially good visit, because there was a lot of education involved,” says manager Mike Haines. “We had a big group going out, with a mix of new and more experienced people, but everyone who was there really wanted to learn.” The team spent a day and a half with Joan walking through a variety of bogs on the property. “We looked at different varieties in different locations and looked at several factors,” Mike says. “One Stevens bed might need ten pounds of nitrogen, but we can’t assume the next bed needs the same. It depends on location, when the water comes off, is it an established bed or a young bed…all kinds of things.”

Tim Bourgeois and Matt Stiles both met Joan for the first time this year and say they really learned a lot. “Fertilizer applications and the specific requirements for cranberries are interesting to learn about,” Tim says. “The how, the what, the why. Cranberries are very different from other crops; they need less fertilizer than other crops do, and the water requirement is different, so you need a good, solid, accurate baseline for what stage they should be at by this point in the growing season. But Joan anticipated a lot of the questions I had in my head and answered as we went through everything, bog by bog.” He says it’s a work in progress: “I’m still trying to get a mental picture of what color plants should be during their normal growth stages so I can also know what problematic coloring looks like.” Matt agrees: “We seem to be on the right track with everything, and it was really informative; she showed us exactly what to look for.”

Things are a little different this year, as well. “We had to make some changes due to the cold wet spring,” says Jeremy Fenstermaker. “We also decided against doing a roughneck fertilizer application this year, so the nitrogen levels are going to be different; typically we’d start with ten pounds on the Stevens and Ben Lear beds but this year we’re going with five.” He attributes some of this to our sanding results. “You can see the difference in plant growth and vigor this year already; we’ll see how it affects insect pressure later on.”

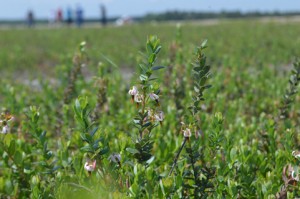

“At this point in the growing season, we are evaluating the plants for fruit potential and trying to develop recommendations for applications between bloom and fruit set. To do this, I look at hook, the length and color of the new upright growth, and the amount and color of old leaves, including looking for leaves from two growing seasons ago,” Joan says.