A niche crop like cranberries often has niche challenges! One of the toughest of those might be surprising to some people: the tundra swan. Tundra swans migrate to the area every year from Alaska and northwestern Canada and are particularly fond of red root, a weed that competes with cranberry vines for nutrients. When they fly in to feed, they not only tear out the red root, they also tear out vines and leave enormous holes that damage the beds themselves.

Since the swans are a protected species, growers have had to come up with a harmless solution to keep them safely away from the bogs. At Pine Island our PIICM team has been installing swan string for several years. The strings help keep the swans out of the bog by limiting the space available. “Swans are like a commercial airliner,” CEO Bill Haines says. “Having the strings up disrupts their attempt to both land and take off again.” Not all of the bogs are strung; our team maps them out where we have found red root and where the swans have been spotted. Just three acres of swan damage can give us a loss of 200 barrels per acre, or even more, depending on the variety. That takes three years to come back.

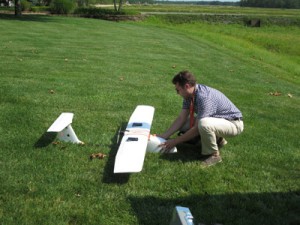

When setting up swan string, the team places rebar in the ground along the longer sides of a bog, about every 75 feet. On the ends of the bog, the team walks it out and determines how many lines they’ll need to run lengthwise though the center. Once the rods are laid out on the dam, a team of three to five people gets into the bog and walks the string across. Once the entire bog is strung, the team goes back in and puts up poles, which are used to keep the strings out of the water so that they don’t freeze. They’re placed in a checkered pattern, not necessarily on every line. The poles can either be cedar posts or recycled irrigation pipe. In addition to the recycling/environmental aspect, reusing the irrigation line is lighter and easier to handle.

Last year, our team installed almost one million feet of swan string, which come out to about one hundred and eighty-seven miles. That’s a lot of walking!

Our team has also adopted a backup method in the past few years: an Agrilaser. From their website:

Deterring pest birds from open and semi-open spaces has long posed a costly and nagging challenge to property owners and managers. While noisemakers like propane cannons can scatter bird pests, they can also be disruptive and must be repeated often to keep birds from coming back. Lethal means of bird control—poisons, pellet guns and inhumane traps—are illegal in many areas, as many birds are protected by law. Bird B Gone’s Agrilaser® provides an effective, humane solution. It uses advanced, patented optical laser-beam technology to harmlessly repel pest birds over great distances—up to 2,000 meters. The handheld device is silent and completely portable. Pest birds react to the green beam as they would an approaching car, so they flee the area. Yet, unlike some deterrent devices, birds will not get used to the laser beam’s implied threat.

With some trial and error around timing and placement, our team found that it does have some effect. “You’d think they’d stay away with all the equipment around, but they don’t,” says Matt Giberson. “But since it’s been effective the past couple of years, it’s good to have a backup to keep both the bogs and the birds safe.”