In our efforts to make us better at what we do as well as improve our efficiency, our team holds occasional meetings to bring everyone up to speed. “We talk about what we’ve just finished, what’s going on next, what our goals are,” says GM Fred Torres. “This way everyone’s on the same page. We’ve had a lot of bad weather, so we’ve been constantly re-evaluating the plans; we’ve struggled with that all winter. But the new boxes are 40% done. 20% of the sprinklers are already in. We’re doing what we need to do.”

PIICM manager Cristina Tassone has also been keeping her team busy. “The ICM offices are almost ready,” she says. “The ICM team’s been putting together furniture and we’re just about ready to move in!” She also told the team to keep an eye out for new faces. “We’re in the middle of the interview process for some open positions, so some of the candidates have been here for farm tours.”

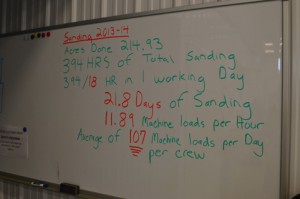

Best of all, though, is that our team has finished this year’s sanding!

Supervisor Matt Giberson headed up the sanding team this year, and was pleased with the outcome. “The weather made it tough, but even with that things went well,” he says. “I was very pleased with how everything turned out. We sanded almost 215 acres over the course of 21 non-consecutive days, averaging 107 machine loads per crew.”

“The shop did a really great job with equipment maintenance,” Matt says. “We had no breakdowns that required shutting a crew down; there were some minor events that we fixed ourselves and only a couple of things where we needed to call for the equipment team.” He was also pleased at some of the new equipment. “The sanding box, on average, saves us about ten percent of the sand, and we actually move at a faster pace with it. That saves us from cleaning ditches in the spring, wasting sand on the dams, and extra work with dredging, screening, and hauling. It takes a little longer to move from one side of the bog to the other, but the team has been brainstorming solutions that should help us improve on that next year.”