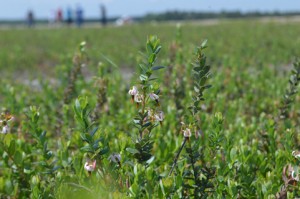

Every year around this time, we get a visit from soil scientist Dr. Joan Davenport! A former researcher for Ocean Spray, Joan works with Pine Island to provide guidance on fertilizer, water, and nutrients, as well as general integrated crop management. “At this point in the growing season, we are evaluating the plants for fruit potential and trying to develop recommendations for applications between bloom and fruit set. To do this, I look at hook, the length and color of the new upright growth, and the amount and color of old leaves, including looking for leaves from two growing seasons ago,” Joan says.

“I’m still trying to learn about cranberry nutrition myself, so it’s always a good visit,” says manager Mike Haines. “We try to cover the whole farm section by section, accounting for variety, location, if a bed has been sanded this year . . .if it hasn’t been sanded for a while that will affect requirements, as well. We also look at crop size the previous year. We’ll try to cover all of those things and then get her thoughts, as well as go over our decisions that we’ve already made this season. For example, Nadine had a big crop in 2016 and we’ve already made some nitrogen applications, and Joan thought that was the right call.” Conversely, he says, it’s also good to know when she disagrees on a decision and why. “This way, we can apply her advice throughout the rest of the season.” Mike also likes seeing her take on other issues as well. “We had some frost damage so I had some questions about that,” he says. “Do we reduce the amount of fertilizer since theoretically the crop potential has decreased? Because we don’t want to put a lot of fertilizer on just for vegetative growth.”

Joan also took a look at our younger beds. “To evaluate new plantings for fertilizer needs, there are slightly different strategies depending on the age of the planting and whether the planting was made from pressed in vines or using rooted cuttings,” she says. “The general philosophy for management is to focus on root development in the first year, then shoots the following year, and then beginning fruit production in year three. If the beds are not well established by year three, it is best to maintain practices to minimize fruit set. The reason for this is that fruit production requires many of the plant’s resources (nutrients, water, carbohydrates) and setting a significant crop prior to plant establishment will delay the ability to get to the desired situation where the roots/shoots/fruit are in equilibrium and can sustain long term production. Using rooted cuttings means that while the plant must still develop a root system in the soil it is planted into, it does not need to utilize the matter stored in the leaves and wood to initiate and grow leaves – this has already occurred. Thus, when rooted cuttings are planted, there is about 1/2 of a growing season “gained”, however it still remains best for focus on roots plus runner development in years 1 & 2. This is an advantage over the use of pressed in vines, where there is a ‘cost’ to the cutting to establish the root system.”

“We’re all kind of learning the nutritional requirements for new Rutgers hybrids along with her,” Mike says. “We’ve been slowly increasing the amount of fertilizer from year to year, which makes sense since the newer varieties were bred to produce a larger crop. For example, with a bed of Early Blacks, we might put 25 lbs of nitrogen per acre, but double that for Crimson Queen.”

Overall, it was another productive visit with Joan, and we’re looking forward to seeing her again this summer!